- New

- Out of stock

The beeswax foundation machine is the perfect solution for beekeepers who want complete control over the quality of their wax. With this machine, you can transform your own wax into embossed foundation sheets without relying on external suppliers, ensuring 100% purity and chemical-free production. This is especially important for organic beekeeping or for those who want to avoid adulterated wax containing paraffins or chemical residues.

Why produce your own beeswax foundation?

The commercial beeswax foundation market often raises concerns about quality and composition. By making your own foundation sheets, you guarantee that you are working with pure beeswax, free from additives or chemical residues. Bees also accept their own wax more readily, making comb construction faster and more efficient. Another key benefit is the ability to recycle wax recovered from cappings and old combs, optimizing its use without relying on third-party suppliers.

How the machine works

This machine transforms melted beeswax into embossed foundation sheets with precise cell patterns using a silicone mold cooled by water. The circulating water helps the wax solidify properly, preventing cracks or deformations.

Installation and cooling system

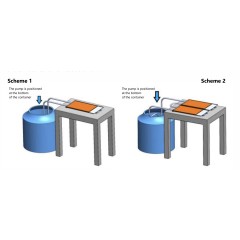

For proper operation, the machine requires a continuous water circulation system, which includes the use of a submersible pump. This setup ensures stable cooling and prevents the wax from solidifying too quickly or cracking.

• Water tank: A container of at least 50 liters is recommended for continuous water flow.

• Submersible pump: It should have a minimum flow rate of 1,000-1,500 liters per hour and a lift height of at least 1 meter to maintain a steady water flow.

• Tubing connections: One tube carries cool water from the tank to the machine, while another returns warm water to the tank, ensuring a continuous cooling cycle.

• Water temperature: Must be maintained between 23°C and 32°C. If the water gets too warm, adding cool water is recommended to regulate the temperature.

For increased production capacity, multiple machines can be connected to the same water system, optimizing efficiency.

Foundation sheet production process

1. Heat the beeswax to 130°C to remove impurities, then cool it to 65-72°C before pouring.

2. Spray the molds with a water and soap solution to prevent the wax from sticking.

3. Pour the melted wax into the mold and allow it to cool using the water circulation system.

4. Carefully remove the wax sheet by peeling off the top part of the mold first.

5. Clean any wax residue from the metal parts after each use to maintain optimal performance.

Technical specifications

• Production time: Approximately 3 minutes per sheet

• Foundation sheet sizes: Various formats available, ranging from 390x195 mm to 420x270 mm

• Water cooling system: Requires a minimum 50-liter tank and a submersible pump

With this machine, beekeepers can produce their own high-quality foundation sheets, ensuring full traceability and control over the materials used in their hives. A key investment for those who want independence and better colony management.